Summary:When designing an energy meter shunt, it is necessary to take several factors into consideration. Fi...

When designing an energy meter shunt, it is necessary to take several factors into consideration. First, the shunt must be properly sized to ensure that it can handle the current running through it without getting too hot or melting. Additionally, the shunt should be correctly calibrated so that it can accurately measure current. This can be accomplished by using Ohm’s law to determine the shunt resistance and then dividing this value by the current rating of the shunt.

Shunts are used in many different applications, including power monitoring and measuring systems. They are particularly useful for devices that need to protect themselves from high voltages, as they can sense currents and alert the user when a dangerous level is reached. Shunts also offer a wide range of benefits over CT, such as a small footprint and immunity to magnetic fields. Shunts are ideal for use in applications that require high accuracy and are not sensitive to phase shift, such as solar inverters or process monitoring.

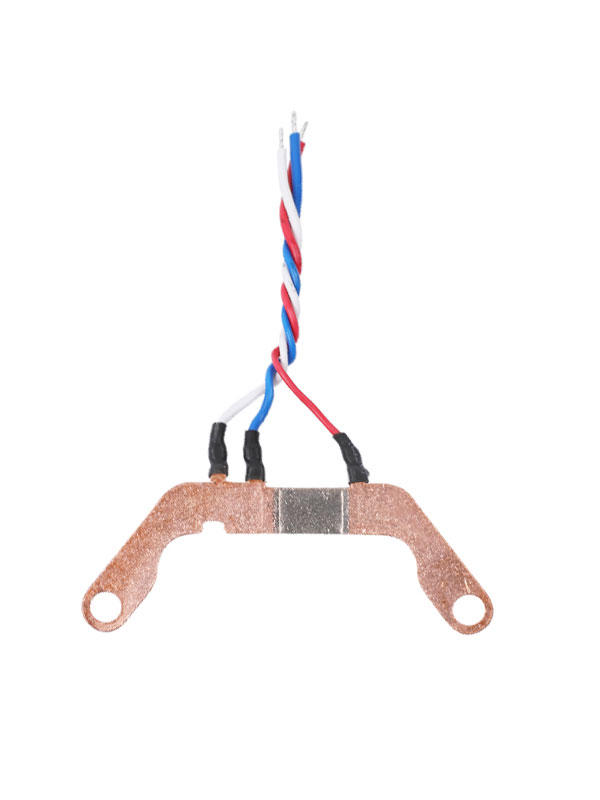

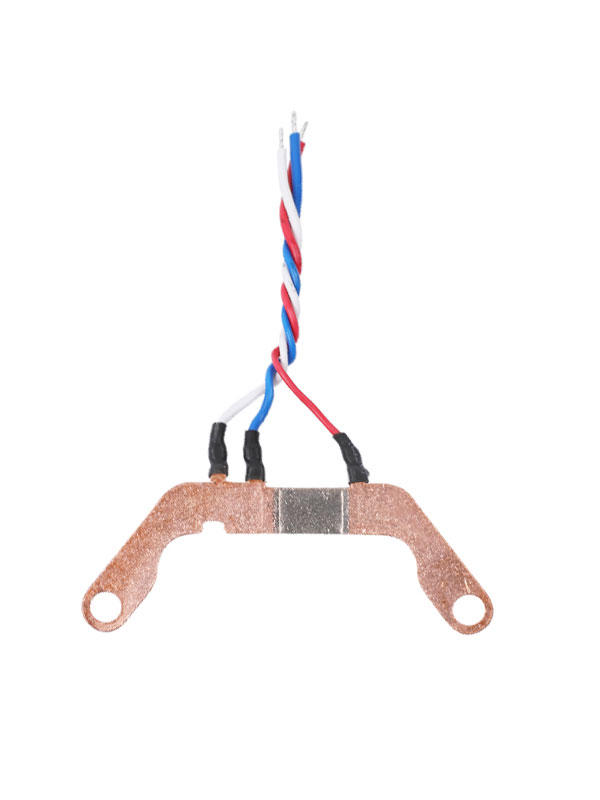

There are a few variants of current shunts that are used in different applications, each designed for specific applications. For example, there is the 2-terminal shunt, which features a resistive element between two copper frame terminals. This type of shunt is commonly used in battery monitors to detect over-current, and it can trigger an alarm when the current reaches a predetermined threshold. Another type of shunt is the thermistor-based shunt, which uses a thermocouple to measure temperature. It can be used to monitor the internal temperature of a circuit, which is critical for many applications.

In addition to a battery monitor, a shunt can also be used in a vehicle’s charging system to track battery usage. The shunt can be connected to the negative cable that connects the battery bank to the electrical circuits, and it is then used to measure the current that flows through the cable. This information can then be displayed on a screen to determine how much power is being used by the battery.

Another common application for shunts is in parallel battery monitoring. The shunt is placed in the parallel battery system so that it can monitor the individual cells. This is especially useful when one cell fails, as it can immediately identify the problem and prevent a complete failure of the system.

Shunts can also be used in three-phase meters to measure current. However, there are some challenges that must be addressed, such as the need for additional isolation between the shunt and the core of the meter. In addition, the shunt must be carefully calibrated so that it can correctly measure large currents without overheating or losing accuracy.

Fortunately, new technology has made it easier than ever to design and build an energy meter with a shunt. With the advent of shunt-based energy metering ICs, designers can easily create a battery monitor that accurately measures current and displays this data on a screen. This is a major step forward in the way that we can monitor batteries and make sure they are not over-charging or approaching their end of life.