Summary:A magnetic latching relay is a type of relay that uses a magnetic field to maintain the state of the...

A

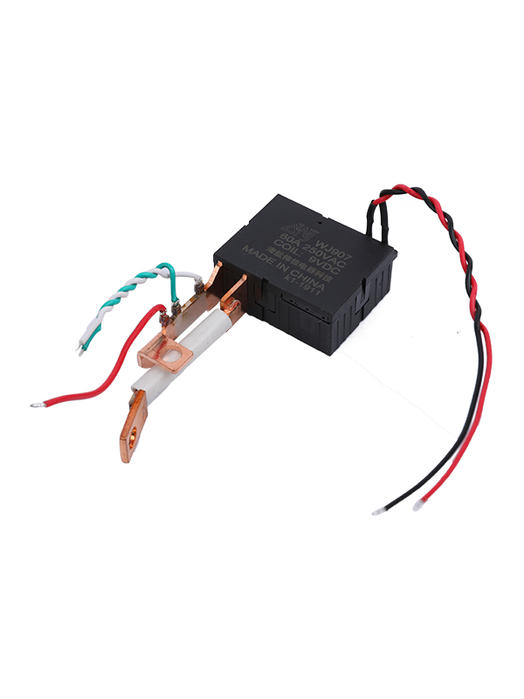

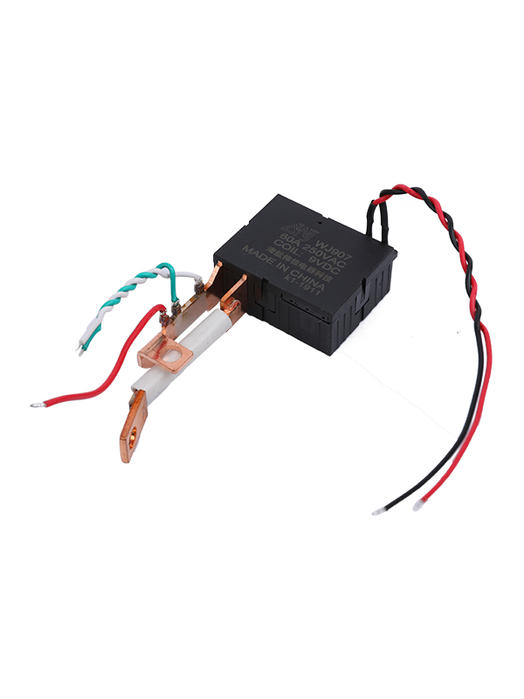

magnetic latching relay is a type of relay that uses a magnetic field to maintain the state of the contacts, instead of using a continuous supply of power. The relay has two coils, a "latching coil" and a "release coil." When the latching coil is energized, it creates a magnetic field that attracts a movable core, which causes the contacts to close. When the release coil is energized, it creates a magnetic field that opposes the latching coil, which causes the core to return to its original position and the contacts to open.

Magnetic latching relays have several advantages over other types of relays. Because the contacts are held in place by a magnetic field, they do not require a continuous supply of power to maintain the state of the contacts, which makes them more energy efficient. Additionally, because the contacts are held in place by a magnetic field, they are less likely to wear out or become damaged over time.

Magnetic latching relays are commonly used in a variety of applications such as lighting control, HVAC systems, alarm systems, and industrial automation. They are also used in applications where the relay needs to maintain its state even if the power is lost, such as emergency lighting and battery backup systems.

The relays are also available in different variations based on the application. There are double coil latching relays, which need two separate coils to toggle the state of the relay, and there are bi-stable relays which have only one coil to toggle the state of the relay, which is more energy efficient.

1.Small volume, big switching power and low consumption

2.Coil instantaneous pulse driving and without fever

3.Stable permanent magnet force and save energy

4.High contact pressure, low contact resistance, working stable and reliable, anti-vibration and anti-shock.

5.Use manganin welding, low material temperature coefficient and compact structure.