Summary:Transformers are made up of a number of different components. These components include the tank, whi...

Transformers are made up of a number of different components. These components include the tank, which protects the windings and core of the transformer. It also provides a space for the transformer's oil. It can be made of steel or aluminum and comes with lifting hooks and cooling tubes. While steel tanks are more common, aluminum sheets have the advantage of being lighter and easier to handle. Other important parts of a transformer include terminals and bushings. These components are used to connect incoming cables and supply and load circuits.

The primary windings in a transformer are wound on the core. This core helps to regulate the magnetic flux in the transformer. It is not a solid steel bar but rather is made of thin, laminated steel sheets. The construction of the core is important because it helps to reduce the amount of heat that is generated during operation. The core of a transformer can be either an inductor or an insulator. Depending on the voltage, current, and frequency of the transformer, the core material will differ.

In addition to the windings, transformers also have secondary windings. These windings are separated from the core by insulators. The insulators protect the transformer from damage. They should have high dielectric strength and good mechanical properties. They should also be able to withstand high temperatures.

The core is a high-grade grain-oriented steel tube that provides a low reluctance path for electromagnetic flux. The primary and secondary windings are made of aluminum or copper. The transformer's secondary winding has a higher number of turns than the primary winding. This helps stabilize the power supply and distribute it normally.

Another important part of the power transformer is the Buchholz relay. This gas-actuated relay is mounted on the pipe connecting the main tank to the conservator tank. The Buchholz relay protects the transformer against internal faults. If a short circuit occurs in the winding, it generates enough heat to decompose the transformer oil. The resulting gases move towards the conservator tank, where they trigger the Buchholz relay. The relay activates and sends a signal to the alarm and trip circuits. If these circuits detect the fault, a circuit breaker disconnects the transformer from the supply.

While electrical transformers have many applications, they are primarily used to transfer electrical energy between two circuits. They work by converting the voltage of distribution wiring to convenient values for circuits. They can also be used to increase or decrease voltage. This is done through Faraday's law of induction, which was discovered in 1831.

The coils of a transformer are heavily insulated and reinforced. They are also coated with insulating varnish. The transformer oil is then contained inside a metallic tank which is positioned on top of the transformer. This tank is half-filled with insulation oil and has a level indicator. A silica gel is also used inside the tank to absorb moisture. The oil is used to cover all parts of the transformer, including the high and low voltage coils.

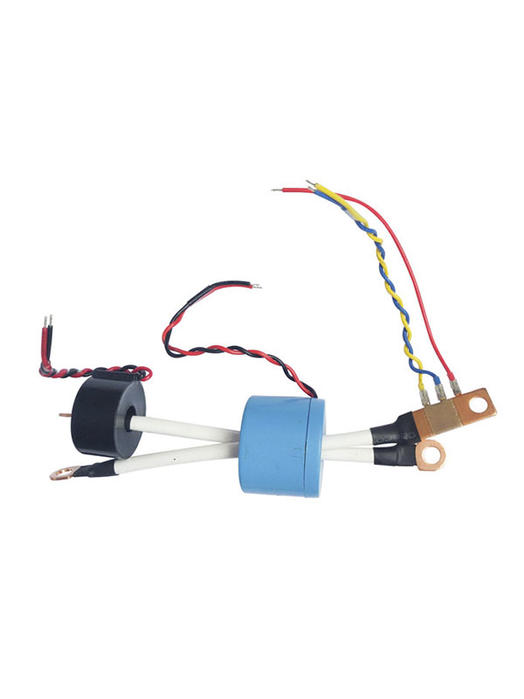

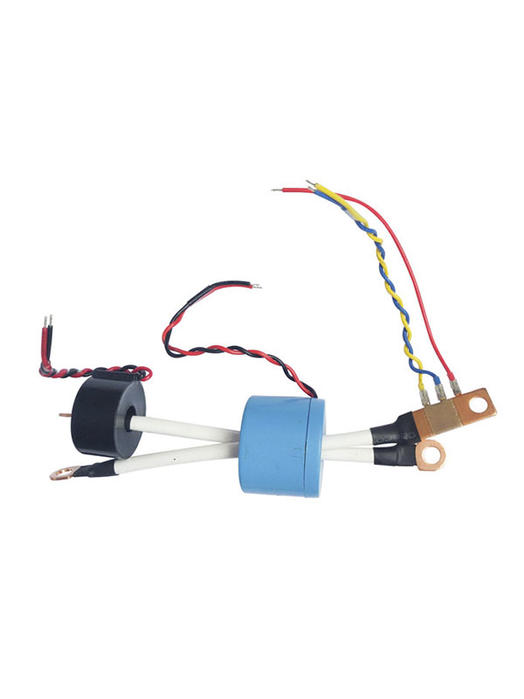

Silicone tube transformer components

Silicone tube transformer components

| Material: |

Copper, iron core, heat shrinkable tube, silicone tube, etc. |

| Accuracy: |

0.1 level, 0.2 level |

| Process: |

Bare bag, epoxy potting |

| Production: |

Production and processing |

1: Working environment temperature: -30 ° C~55 ° C

2: Working environment humidity: relative: 10%~90%: Absolute: <29g/m

3 without condensation 3: Storage ambient temperature: -40 ° C ~70 ° C

4: Working altitude: 0-4000 meters, rated power below 2000 meters, above 2000 meters, for every 100 meters rise, derating 1%