Summary:In many cases, the current measurement system in a smart energy meter requires shunt resistors to fu...

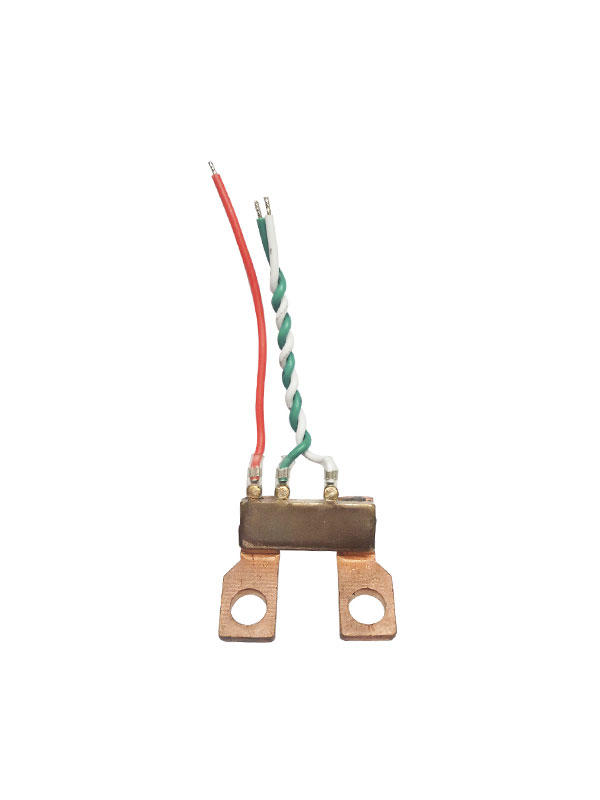

In many cases, the current measurement system in a smart energy meter requires shunt resistors to function. These shunts are used to bypass the direct current passing through the meter to extend the range of the instrument and deliver a millivolt output (to a standard millivolt meter or instruments) in proportion to the current flowing across the shunt. This allows the shunt to be used in applications where it may not be feasible or safe to run copper bus bars from the circuit carrying the current being measured to the metering panel or switchboard.

One common challenge with smart energy shunts is that they require an extremely high resistance tolerance, typically up to 5%. This is the result of the Manganin alloy material itself and its inherent sensitivity to temperature fluctuations in its overall resistance value. This tolerance can be mitigated through calibration and/or the use of a temperature compensated shunt, however, this can add to the overall cost of the assembled meter and requires additional software.

An alternative to these solutions is to trim the shunt resistor. This is done by removing a small section of the resistive element in the area where the resistance values are most critical. This reduces the overall resistance of the shunt and improves its ability to maintain a stable resistance value over a wider operating temperature range, however, this process can adversely impact other key performance attributes such as temperature rise and power rating.

In order to determine if trimming had any negative impact on the temperature rise of a Manganin shunt resistor and its overall power rating we conducted a series of tests on two different samples. First, a type K thermocouple was resistance spot welded to the rear face of each shunt to measure the temperature rise. Then the shunts were powered up to 4 W and rated for the amount of current they could handle over a time period of 24 hours. A four wire Kelvin method was used for all resistance measurements and the results were compared to untrimmed samples.

The data obtained shows that, on average, the trimmed shunt resistors experienced a lower resistance change than their untrimmed counterparts at the same test temperatures. This was due to a combination of factors including the initial oxidation on the surface of the Manganin alloy which increases its resistance, as well as the annealing of impurities and reduction in grain boundary resistance which reduces the overall resistance of the material.

However, the results also showed that the trimmed shunt resistors suffered from an increased rate of change in resistance during the first 24 hours of testing. This was attributed to both the initial oxidation as well as to the shunts adjusting to their new temperature over this time period. It is therefore important to perform proper shunt selection and to monitor the shunts over time for any changes in their resistance values which can indicate a degradation of the shunt resistor performance over its operational life.