Summary:Several types of transformers are available for various applications. Electrical transformers are us...

Several types of transformers are available for various applications. Electrical transformers are used to step up and down voltage levels, and to regulate the electrical current. They are used in the power industry, military, and commercial industries. They are available in different sizes and power ratings.

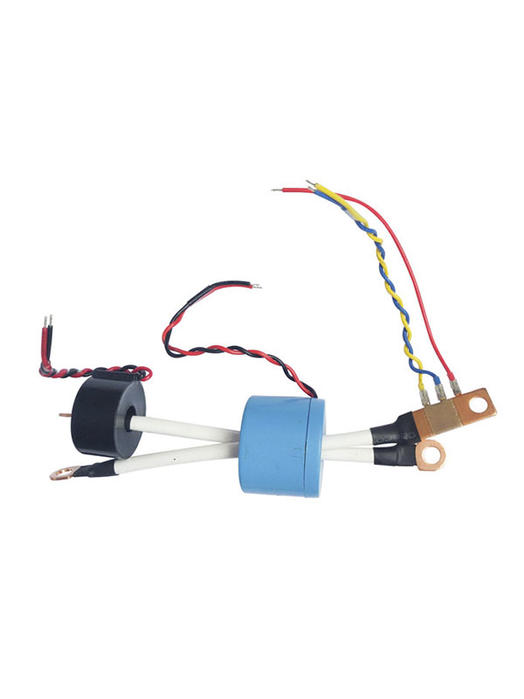

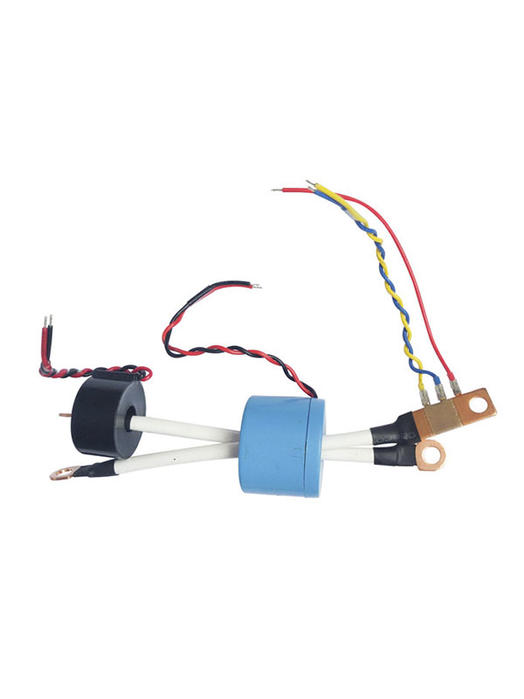

A transformer consists of several parts including the core, windings, cooling tubes, and insulating material. The core supports the windings and provides a magnetic circuit. The windings are made of copper and are insulated. The insulation material is made of paper or card boards. In addition, the insulation material can be made of bakelite tubes or glass sleeves varnish. The transformer is protected by an epoxy bushing, which helps in keeping the transformer durable.

The transformer core is made from soft iron, which is capable of reducing eddy current losses. It also provides a low reluctance path for the flow of magnetic flux. The diameter of the core is directly proportional to copper loss, and inversely proportional to iron loss. It also helps in reducing the Hysteresis loss. The diameter of the core is standardized at 0.18 mm to 0.35 mm.

The main parts of a transformer are the core, the windings, the insulation material, and the oil. The oil in the transformer is used to cool the coil assembly. The oil is filtered through a "Stream Line Filtering plant". The oil used as a coolant is compliant with the IS: 335. Oil filled distribution transformers are available in single phase, three phase, and low voltage. The oil is also cooled by cooling tubes.

The windings of the transformer are made of copper. A thin layer of laminations is stacked to form the core of the transformer. The diameter of the core is usually a standard gauge. The windings are wrapped around the center of the core. In addition, a number of terminals are mounted on bushings that are connected to the winding ends. The coils are reinforced, and the windings are pre-gnated with insulating varnish.

1: Working environment temperature: -30 ° C~55 ° C

2: Working environment humidity: relative: 10%~90%: Absolute: <29g/m

3 without condensation 3: Storage ambient temperature: -40 ° C ~70 ° C

4: Working altitude: 0-4000 meters, rated power below 2000 meters, above 2000 meters, for every 100 meters rise, derating 1%